The planet is facing a climate emergency. Governments and companies are under mounting pressure to curb emissions and create a more sustainable world. At the same time, the pace of technological change is faster than ever as we become more connected. Lighting is contributing to solving both issues in some very surprising ways.

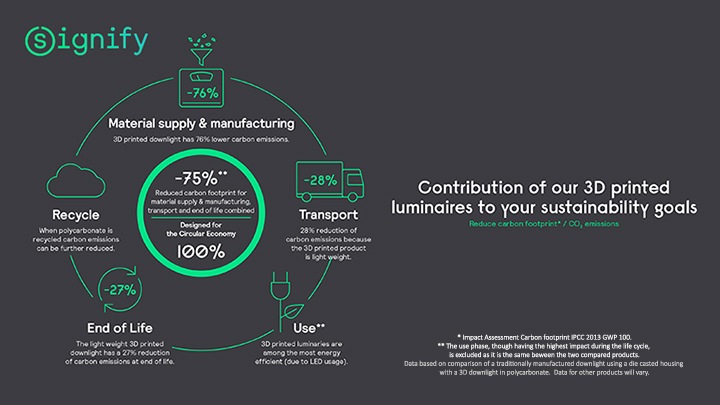

Signify is excited to expand its offering of 3D Printed Luminaires with 3D printing factories in the US, India and Indonesia. The company has perfected this highly flexible, more sustainable form of manufacturing, using a 100% recyclable polycarbonate material, which allows luminaires to be designed or tailored to customer’s exact needs and recycled at the end of their life. This sustainable form of manufacturing supports a circular economy in the US and Europe by establishing and expanding the first product line since the creation in 2017.

Signify’s investment in 3D printing further illustrates the company’s commitment to better serving its customers while reducing their, and its own, carbon footprint. A typical manufactured luminaire (excluding electronics and optics) has a 47% lower carbon footprint than a conventionally manufactured metal luminaire. Nearly every component may be reused or recycled, supporting the concept of a circular economy.

“By offering 3D Printing solutions locally our specification and design community can work with the 3D Luminaire group to develop a concept on paper, see that concept in days, and a fully developed product in a matter of weeks. Compare this to the traditional product development time frame of 10-14 months from concept to final design. It is truly groundbreaking. Signify also has an Industrial design group that our design community can work with, conveniently located in our Burlington Massachusetts office to work out customized design concepts.”

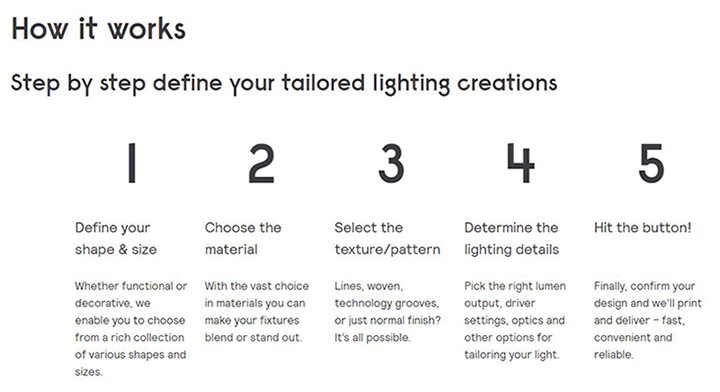

Customers will also have the ability to tailor existing designs in a newly US launched web based tool.

Try it yourself with the 3D Printing online configurator.

Signify 3D printed luminaires have a lower carbon footprint than traditionally built metal luminaires. They weigh less, which enables Signify to reduce the carbon emissions in shipping by 35%. By keeping production in the US, we reduce the footprint even further. And of course, LED lighting is more energy efficient than conventional lighting.

November 14, 2023

How lighting technology can help reduce risks to migrating birds