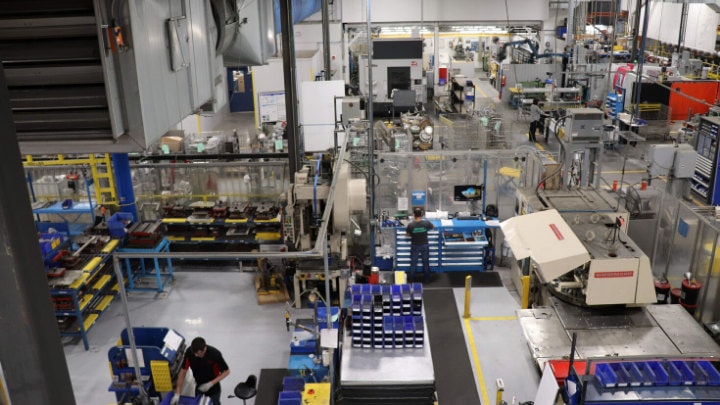

The Lumec factory, located in Boisbriand, Québec has been through a lot of LEAN changes in the past two years. These changes helped to achieve a time and cost reduction for the factory, as well as maintain a high-level product quality. Here’s a look at the different LEAN phases that have been taking place since 2017.

Step 1: Logistics

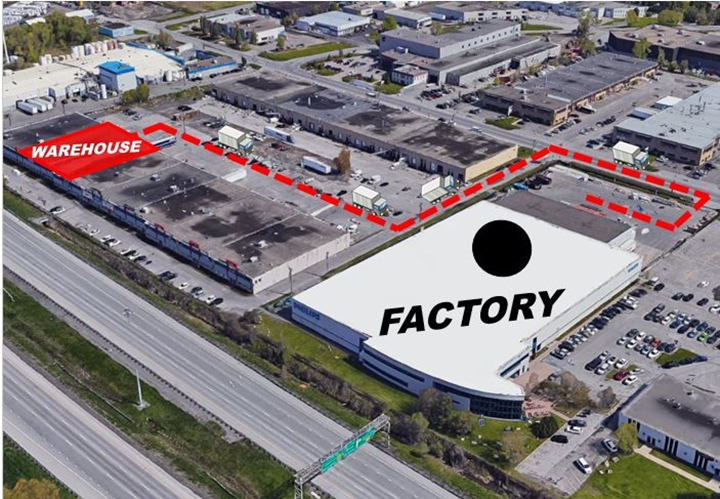

Two years ago, the Lumec factory was in it’s the current location but the warehouse was in another building, 200 meters (650 ft) away. Travelling back and forth between those two locations caused important delays in production while highly increasing the cost of handling. The decision to close the warehouse and incorporate it within the same building came with a lot of problems to solve. However, removing non-used inventory helped the factory to reduce loss as well as improve material flow: less turnaround time, increased « right on first time », and better use of our time.

Lumec factory and warehouse prior to move (2017)

A multidisciplinary team worked on the plant reorganization project to enhance factory life. They created a brand-new welding section which, again, helped reduce turnaround in production time. They evaluated the actual machinery to optimize its use. They also established new ways of working by standardizing the warehouse section (pallet size, stock allocation, stock uniformization).

All these great changes were demanding but had a great impact for both business and people. Customer lead time dropped from 10 days to 2 days of production because of that material flow improvement. But the LEAN team was just getting started.

Step 2: Environment

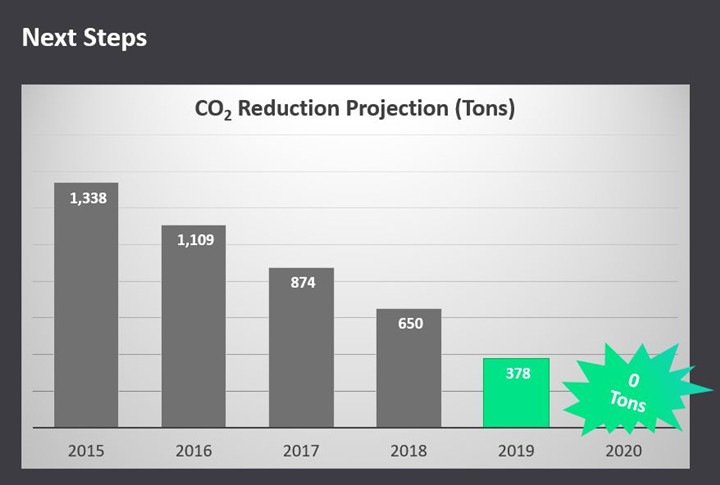

Having in mind to evolve the LEAN mindset within the factory, the team came up with some environmental ideas. In 2017, the entire ventilation system was changed to enable temperature control across the factory. This major change first helped to provide a more comfortable climate for our employees through the seasons, while considerably reducing the break period needed. It was also beneficial for our gas consumption which is not insignificant.

Furthermore, switching boilers to electric energy was another important change in 2018 where we calculated a global reduction of 55% on our energy consumption without impacting our ratio. Drying oven, regular oven, heat treatment basins, central heating; all directly connected to natural gas central system. Needless to say, this generated a cost reduction to the factory as well as connecting us to environmental values that Signify has at heart.

Let’s not forget the Zero Waste to landfill project, overseen by the LEAN team, that took place in 2019. It's 5.2 tons of waste that Lumec sent to an Energy Recovery Center instead of landfill site. Our factory also conducts waste audit to increase the rate of recyclability and composting in order to improve our ecological footprint, on a daily basis.

The past 2 years allowed the employees to develop a sense of belonging while everyone highly participated in different spheres for many of these projects.

Working together, we can definitely accomplish more and make a difference.

Step3: More Improvements

Feeling motivated, the LEAN team continued to investigate new improvements. Since mid 2019, they really focussed on many reorganisations to create better workflow. A new pole section was created for better use of space, allowing us to work on taller poles without configuration problems, and also, insource the curved poles within the factory. The manufacturing section was also reorganized and realigned to create a natural material flow. The workers in the Lumec plant were thrilled to acquire a vertical carousel, which serves as an oversized automatic dispenser, that helps to optimize the space and eliminate any handling risks (safety first!). Through these numerous changes, several analyses were done in different processes to increase product quality.

Next steps

All these game changers are only the beginning.

For 2020, the LEAN team is actively working on new projects that will bring the Lumec factory to next level of achievements. One of the objectives is to reuse the energy from one oven to another, which would decrease the equipment energy consumption of 88% and, at the same time, reduce our CO2 uptake of 150 tons.

November 14, 2023

How lighting technology can help reduce risks to migrating birds