Coatings in lamp manufacturing are used for different applications. We have several coatings in our portfolio: interior protective glass coating for TUV lamps, adhesive agent for fluorescent lamps, reflector coating for low wattage Metal Halide lamps and interior color coatings (GLS and TL).

Features and benefits:

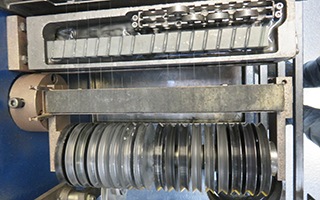

Lubricants are designed to achieve severe reductions when drawing tungsten or molybdenum wire. These lubricants will help you to improve your wire quality and reduce wire breaks to produce a top quality finished wire.

Features and benefits:

A uniform layer of emitter applied on the electrodes of fluorescent and high intensity discharge lamps lowers the work function of the electrode; ensuring starting and the lifetime of the lamp. We offer a complete emitter product range for all types of discharge lamps.

Features and benefits:

Getters are used to absorb impurity gasses in incandescent lamps. This contributes to a clean lamp atmosphere which ensures the lifetime of the lamps.

Features and benefits:

The inks are used to mark and identify lamps and come in two types: stamp-pad inks and pad printing inks. Stamp-pad ink has a good printing behavior for clear marking. Fixation is done by heating. Pad printing ink has a different marking process and won’t have to burn in.

Features and benefits:

The purpose of flux is to facilitate the soldering process. It removes impurities (e.g. oxides) from the surface of the cap or base and provides a proper solder flow.

Features and benefits:

Products

Our lamp components find their origin in the manufacturing of lamps, however these same components or derived components can also be used for other purposes.

Technologies

The technologies we are using to produce lamp components can also be applied for other non-lighting products.