December 11, 2020

Circular venture brings 3D printing to North America

With ambitious sustainability targets to live up to, Signify is serious about the need to reduce waste while supporting customers’ needs, too.

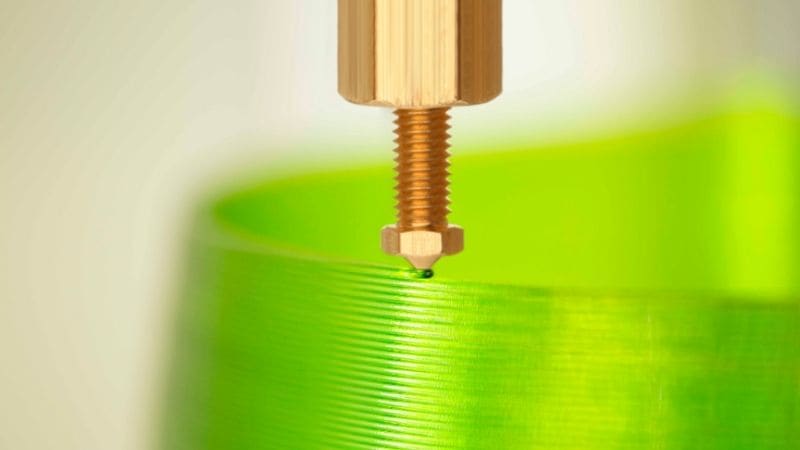

These two goals perfectly align in the case of Signify’s 3D printing venture. I’m speaking to Matthew Wall, Product Marketing Lead for 3D printing in North America. Signify has already made strides in 2020 in North America and India by establishing factories that can print and produce products locally. Signify is establishing a larger footprint in this new technology and is the only major manufacturer to be producing 3D-printed lighting products on an industrial and commercial scale.

“Signify already has some experience of what’s worked well in Europe. This is where we started with our go-to-market plan: we combined what’s been done in Europe with our knowledge of what works in North America, and our voice of customer research,” explains Matthew. “As we expand our North American portfolio we will also be introducing products and variations that meet the need of our local market.”

Matthew and his team are based in Burlington, Massachusetts with an established Signify factory in Littlestown Pennsylvania. With multiple print hubs around the world, Signify is manufacturing these custom luminaires locally, eliminating long-distance shipping and slashing each product’s carbon footprint. At the end of the product’s lifecycle, the materials can be simply shredded and recycled.

“We spoke with an interior designer who wanted individual room numbers as part of the lighting design for a hotel. We spoke to a retailer who wanted to use lighting to show the numbers of the cash registers that were open or closed. You can have a sports stadium where every lamp is lit up with the team colors, with the team logo integrated. With 3D printing, you can even design different shapes that resemble baseballs, basketballs or even soccer balls. It gets people’s imagination going in exciting ways. Details like this are unique. Only Signify’s 3D printing capability can offer this level of customization on this scale.”

Signify (Euronext: LIGHT) is the world leader in lighting for professionals, consumers and the Internet of Things. Our Philips products, Interact systems and data-enabled services, deliver business value and transform life in homes, buildings and public spaces. In 2023, we had sales of EUR 6.7 billion, approximately 32,000 employees and a presence in over 70 countries. We unlock the extraordinary potential of light for brighter lives and a better world. We have been in the Dow Jones Sustainability World Index since our IPO for seven consecutive years and have achieved the EcoVadis Platinum rating for four consecutive years, placing Signify in the top one percent of companies assessed. News from Signify can be found in the Newsroom, on X, LinkedIn and Instagram. Information for investors is located on the Investor Relations page.

December 17, 2024

Transforming Dubai’s iconic buildings with connected lighting from Signify