January 10, 2022

From new circular products and services to zero waste to landfill and zero plastic packaging. How do we transition to a more circular economy?

Today's linear production and business models consume the resources of 1.8 Earths, much more than what is available to us1. But there is a solution: transitioning to a circular economy. With sharing, leasing, reusing, repairing, and recycling existing materials at its core, a circular economy helps us retain value and minimize waste.

At Signify, sustainability is key to everything we do. We are committed to contributing to the transition to a circular economy and achieving Sustainable Development Goal 12: Responsible consumption and production.

A shift toward a sustainable circular economy is all about creating and preserving value. Our actions range from creating new products to delivering services that fit into the circular economy ecosystem to minimize waste. So, let's take a closer look at each of our actions.

Signify created a set of sustainable design rules helping us continuously optimize for circularity and lower the carbon footprint of our new products. Based on this, we created four categories of circular lighting solutions to enhance lifetime, reusing, refurbishing, and recycling. As part of our Brighter Lives, Better World 2025 sustainability program, we will double our revenues from circular products, systems, and services to 32% by the end of 2025.

The next category is Circular Components. These components can easily be replaced and are made of recyclable parts, such as drivers, controls, and LED boards. Their specifications reach the most rigorous standards for durability and failure rates. And by only having to replace a single component when it breaks or reaches the end of its lifetime, we can extend the lifespan of a luminaire beyond the lifespan of its parts.

The third category is Intelligent Systems which can constantly monitor light fittings. This feature tells us when and where to perform maintenance, cutting down on waste, costs, downtime, and workforce. Further, these systems can optimize light levels; for example, to create the highest levels of energy savings or increase eye comfort.

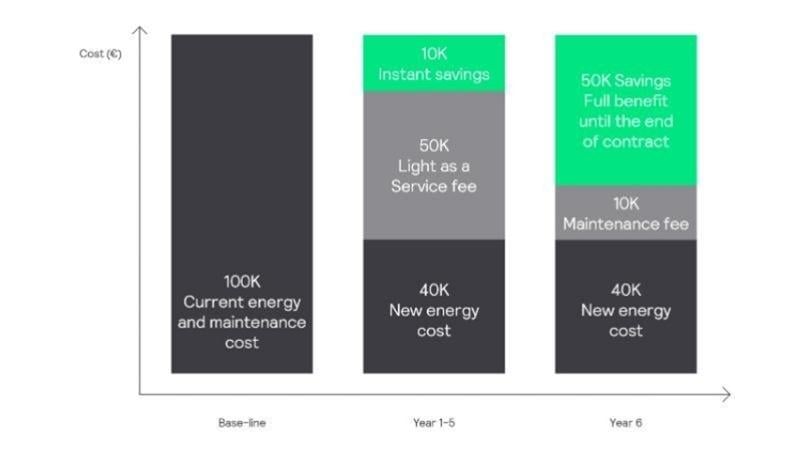

The last category concerns our Circular Services. With Light-as-a-Service (LaaS), we provide design, financing, installation, maintenance, and end-of-life management to our customers in a single contract. This allows our clients to pay for the light they use rather than become the lighting system’s owner. We take care of the lighting, so our clients can fully concentrate on running their business.

The technical, sustainable, and financial benefits of service-based lighting sparked a fairly rapid transition. The COVID-19 pandemic accelerated this as it increased the need for our clients to optimize their cashflow.

By offering a financing mechanism, LaaS makes it possible to renovate lighting without an upfront investment. When an existing and conventional lighting system is renovated, the energy savings can be massive. Additionally, the lighting service can generate immediate positive cash flow.

At the end of a LaaS contract, the equipment can be returned to Signify. We will then recover value from end-of-contract products, primarily via reuse or recycling. Having originally designed the product and monitored its actual use throughout its in-service life, we have all the data we need to choose the best scenario for each product.

We closely monitor and report our progress in expanding our circular portfolio. At the end of Q3 2021, 24% of our revenues came from circular products, systems, or services, putting us on track to achieve our 2025 commitment of 32%. While we know that our environmental impact is most significant in the use phase of our products, we also take action in our operations.

When it comes to incorporating circularity in our operations, waste management is a key area of action. In 2016, we committed to sending zero manufacturing waste to landfill. By the end of 2020, we delivered on this target as planned and recycled 91% of our industrial waste. In 2021, our major focus was on including our recent acquisitions in our commitment and driving continuous improvements. We improved our waste separation and waste awareness training, while sharing best practices across other regions.

Going beyond our operations, we want to minimize the waste produced by the consumption of our products. Therefore, we launched a project to eliminate plastic in our consumer packaging, which we will achieve in the third quarter of 2022. This will help society avoid 2,500 metric tons of plastic every year. This is equal to 125 million PET bottles which, placed in a row, would stretch more than 8,000 kilometers (5,000 miles)2.

The first steps in transitioning to a more circular economy helped us unlock value for our clients, partners, and ourselves. The new 3D-printed circular luminaires have an environmental footprint 75% lower than their conventional equivalent. The service-based model enables our clients to take climate action by decreasing their electricity consumption even when economic circumstances don’t allow new investments, while receiving the highest quality in lighting.

To support the transition to a circular economy, we will continue to do what we have committed to do for over 130 years: innovate. Not only in our products, but also in our relationships and business models. To move to a circular economy, we must continue to help our clients see the long-term value of sustainability and product performance.

To conclude, we listen to the words of Helen Micheaux, a senior lecturer in Sustainability: “The Earth will not tolerate another decade of constant production and consumption growth. Business models based on the linear economy of " extract-produce-use-dispose " must end. It is urgent that producers find new ways to create value, consistent with the imperative to reduce material and energy flows. In practice, this means that producers must sell fewer new products and focus their innovation strategies on offering new services that accompany long-lasting products: rental, maintenance, repair, reuse, reconditioning. There are now many initiatives by companies that are moving towards more circular business models, Signify being a good example. This evolution is inevitable if companies want to continue to operate in the decades to come.”

Would you like to learn more? Visit our Circular Economy page.

This blog has been developed by Francois Darsy and Helen Micheaux in collaboration after the publication of the original article.

1 Overuse of Resources on Earth (theworldcounts.com)

2 Based on Signify’s own calculations using PET bottles of 0.5 liters.

Signify (Euronext: LIGHT) is the world leader in lighting for professionals, consumers and the Internet of Things. Our Philips products, Interact systems and data-enabled services, deliver business value and transform life in homes, buildings and public spaces. In 2023, we had sales of EUR 6.7 billion, approximately 32,000 employees and a presence in over 70 countries. We unlock the extraordinary potential of light for brighter lives and a better world. We have been in the Dow Jones Sustainability World Index since our IPO for seven consecutive years and have achieved the EcoVadis Platinum rating for four consecutive years, placing Signify in the top one percent of companies assessed. News from Signify can be found in the Newsroom, on X, LinkedIn and Instagram. Information for investors is located on the Investor Relations page.

December 17, 2024

Transforming Dubai’s iconic buildings with connected lighting from Signify